Services and Process

Services and Process

Forging process services

Our forging process involves multi-station cold forging, applicable to different types of metal materials, including carbon steel, stainless steel, alloy steel, aluminum, brass, etc. Through multiple continuous stamping techniques, we can process raw materials into the desired shape while maintaining their strength and microstructure, ensuring higher dimensional stability and durability of the products.

Key Features:

- Size Range: We can manufacture forgings with a maximum outer diameter of approximately 50mm and a length of around 190mm.

- Production Efficiency: Production speed can reach up to 3400 pieces per hour.

- Room Temperature Forming: Through meticulous process design, forgings are formed at room temperature, eliminating the need for heat treatment, which helps reduce costs, improve production efficiency, and minimize waste.

Application :

Our forging process is commonly used for manufacturing various components, tools, or other metal products. Whatever type of forging you need, we can provide high-quality service.

If you have more questions about our forging process or need further information, feel free to contact us anytime!

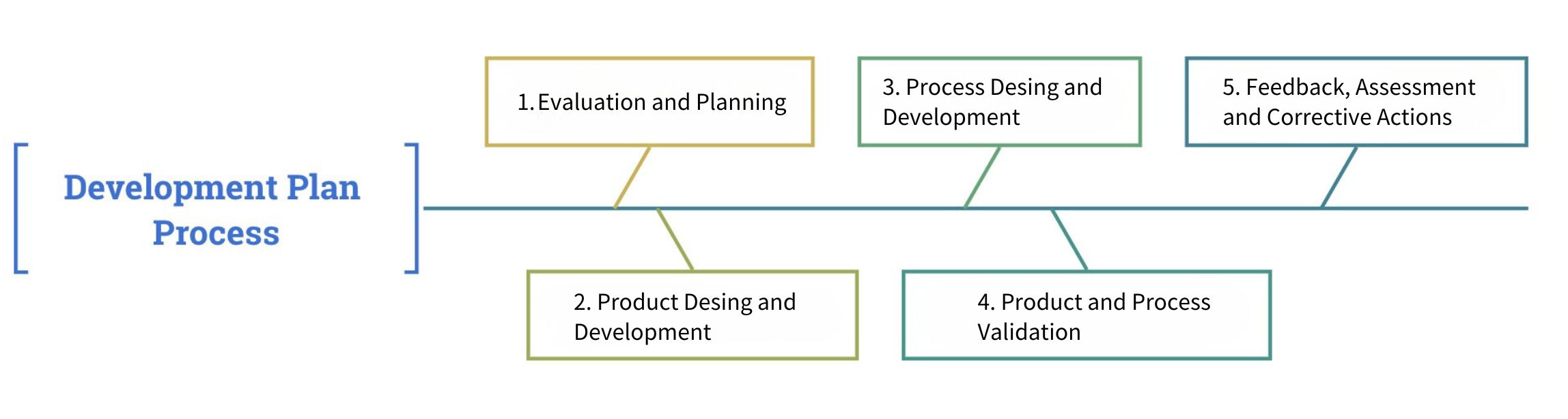

Development Planning Process

Our development planning process is as follows:

- Evaluation and Planning:

We begin by holding an initial product quality planning meeting to define product requirements and development goals. This includes understanding customer needs, conducting a feasibility analysis, and creating a development plan with clear timelines and resource allocation.

- Product Design and Development:

Based on customer specifications, we design detailed engineering drawings. We perform DFMEA (Design Failure Mode and Effects Analysis) to identify and prevent potential risks, while planning for the necessary equipment, molds, and testing tools.

- Process Design and Development:

We review the production process and quality systems, create manufacturing flowcharts, and conduct PFMEA (Process Failure Mode and Effects Analysis). We also plan for trial production, system analysis, and initial process capability studies to ensure a stable and reliable process.

- Product and Process Validation:

Trial production is conducted to verify the process. We analyze the measurement systems and process performance (PPK) before final validation through the PPAP (Production Part Approval Process).

- Feedback, Assessment and Corrective Actions:

After production begins, we gather data from production and customer feedback. Continuous monitoring and analysis help us identify areas for improvement and implement corrective actions to enhance product quality.

These five stages are interconnected, forming a

comprehensive product development and quality management framework that ensures

the final product meets customer requirements and adheres to the highest

quality standards.